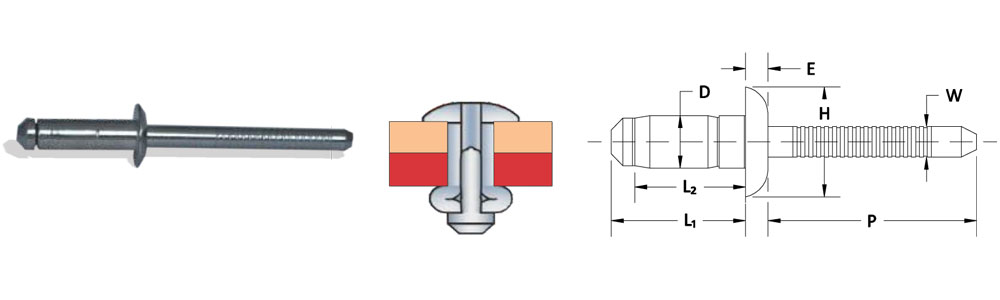

St Bulb and #St Nox Rivets provide a high-strength fastening solution that is ideal for thin sheet metals. St Bulb is steel rivets whereas St Nox is stainless steel rivets. For irregular, oversized, and misaligned holes, St Bulb and St Nox Rivets provide good hole fill the gap. The Stainless steel St Nox Rivets provide good corrosion resistance.

The diameters range from 3.2 mm to 6.4 mm( 1/8 x ¼ inches) and lengths as per various grip range

Material

- Rivet Body – Steel, Mandrel – Steel

Key Features

- High shear and tensile strength

- Retained stem

- Large blind side bearing area

|

St-Bulb Blind Rivet |

||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Nom Rivet Size (mm) |

Nom Rivet Size (mm) |

Rivet Code |

Hole Dia |

Domed Head Dia |

Head Height |

Mandrel Dia |

Mandrel Protrusion |

Domed Head Grip Range |

Material St-Bulb Rivet Body – Steel Mandrel – Steel |

|||||||||

|

D |

L₁ |

D |

L₂ |

H |

E |

W |

P |

Tensile Min. |

Shear Min. |

Mandrel Break Load |

||||||||

|

-0.2 |

Max. |

-0.2 |

Max. |

Min.~ Max. |

Min. |

Max. |

Max. |

Max. |

Min. |

Min.~ Max. |

N |

LBS |

N |

LBS |

N |

LBS |

||

|

3.2 |

9.1 |

3.2 |

6.6 |

4-1 |

3.3~3.4 |

6.05 |

6.65 |

1.20 |

2.10 |

25.4 |

1.0 ~ 3.0 |

1040 |

234 |

960 |

215 |

Min. |

1000 |

225 |

|

3.2 |

11.7 |

3.2 |

9.2 |

4-2 |

3.3~3.4 |

6.05 |

6.65 |

1.20 |

2.10 |

25.4 |

3.0 ~ 5.0 |

1360 |

305 |

Max. |

2200 |

495 |

||

|

3.2 |

14.0 |

3.2 |

11.5 |

4-3 |

3.3~3.4 |

6.05 |

6.65 |

1.20 |

2.10 |

25.4 |

5.0 ~ 7.0 |

2000 |

450 |

|||||

|

4.0 |

10.4 |

4.0 |

7.3 |

5-2 |

4.1 ~ 4.3 |

7.52 |

8.33 |

1.50 |

2.70 |

26.9 |

1.0 ~ 3.0 |

2210 |

497 |

1920 |

432 |

Min. |

2000 |

450 |

|

4.0 |

12.9 |

4.0 |

9.9 |

5-3 |

4.1 ~ 4.3 |

7.52 |

8.33 |

1.50 |

2.70 |

26.9 |

3.0 ~ 5.0 |

2800 |

629 |

|||||

|

4.0 |

15.7 |

4.0 |

12.7 |

5-4 |

4.1 ~ 4.3 |

7.52 |

8.33 |

1.50 |

2.70 |

26.9 |

5.0 ~ 7.0 |

3280 |

737 |

Max. |

3200 |

719 |

||

|

4.0 |

18.1 |

4.0 |

15.1 |

5-5 |

4.1 ~ 4.3 |

7.52 |

8.33 |

1.50 |

2.70 |

26.9 |

7.0 ~ 9.0 |

2000 |

450 |

2640 |

593 |

|||

|

4.8 |

12.1 |

4.8 |

8.6 |

6-2 |

4.9 ~ 5.1 |

9.05 |

10.00 |

1.60 |

3.10 |

26.9 |

1.5 ~ 3.5 |

3040 |

683 |

2880 |

647 |

Min. |

3000 |

674 |

|

4.8 |

14.7 |

4.8 |

11.2 |

6-4 |

4.9 ~ 5.1 |

9.05 |

10.00 |

1.60 |

3.10 |

26.9 |

3.5 ~ 6.0 |

3360 |

755 |

Max. |

4800 |

1079 |

||

|

4.8 |

17.6 |

4.8 |

14.1 |

6-5 |

4.9 ~ 5.1 |

9.05 |

10.00 |

1.60 |

3.10 |

26.9 |

6.0 ~ 8.5 |

4480 |

1007 |

|||||

|

6.0 |

14.0 |

6.0 |

10.0 |

7-1 |

6.1 ~ 6.3 |

10.50 |

12.00 |

2.50 |

4.00 |

30.0 |

1.5 ~ 4.0 |

4320 |

971 |

3360 |

822 |

Min. |

5200 |

1169 |

|

6.0 |

17.0 |

6.0 |

13.0 |

7-2 |

6.1 ~ 6.3 |

10.50 |

12.00 |

2.50 |

4.00 |

30.0 |

3.0 ~ 6.0 |

4320 |

971 |

|||||

|

6.0 |

20.0 |

6.0 |

16.0 |

7-3 |

6.1 ~ 6.3 |

10.50 |

12.00 |

2.50 |

4.00 |

30.0 |

6.0 ~ 9.0 |

6800 |

1528 |

Max. |

7200 |

1618 |

||

|

6.0 |

23.0 |

6.0 |

19.0 |

7-4 |

6.1 ~ 6.3 |

10.50 |

12.00 |

2.50 |

4.00 |

30.0 |

9.0 ~ 12.0 |

6800 |

1528 |

|||||

|

6.4 |

17.3 |

6.4 |

12.5 |

8-1 |

6.6 ~ 7.0 |

11.50 |

13.00 |

2.70 |

4.20 |

30.0 |

1.5 ~ 5.5 |

5440 |

1222 |

8880 |

1996 |

Min. |

5800 |

1303 |

|

6.4 |

21.3 |

6.4 |

16.5 |

8-2 |

6.6 ~ 7.0 |

11.50 |

13.00 |

2.70 |

4.20 |

30.0 |

5.0 ~ 9.0 |

Max. |

7800 |

1753 |

||||

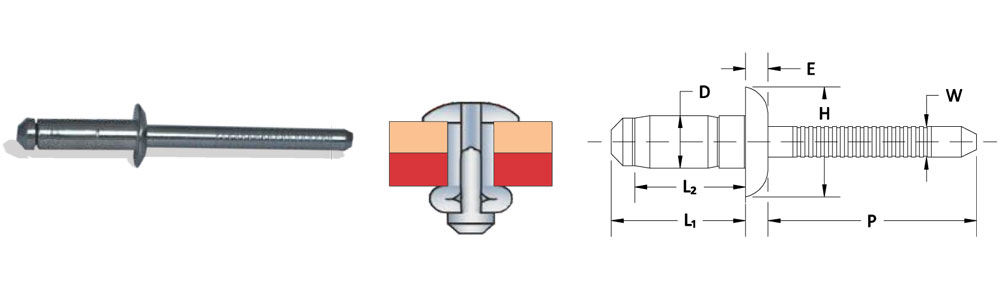

Material

- Rivet Body – Stainless Steel,

Mandrel – Stainless Steel

Key Features

- High shear and tensile strength

- High corrosion resistance

- Retained stem

- Large blind side bearing area

|

St-Nox Blind Rivet |

||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Nom Rivet Size (mm) |

Nom Rivet Size (mm) |

Rivet Code |

Hole Dia |

Domed Head Dia |

Head Height |

Mandrel Dia |

Mandrel Protrusion |

Domed Head Grip Range |

Material St-Nox Rivet Body – Stainless Steel Mandrel – Stainless Steel |

|||||||||

|

D |

L₁ |

D |

L₂ |

H |

E |

W |

P |

Tensile Min. |

Shear Min. |

Mandrel Break Load |

||||||||

|

-0.2 |

Max. |

-0.2 |

Max. |

Min.~ Max. |

Min. |

Max. |

Max. |

Max. |

Min. |

Min.~ Max. |

N |

LBS |

N |

LBS |

N |

LBS |

||

|

3.2 |

9.1 |

3.2 |

6.7 |

4-1 |

3.3 ~ 3.4 |

6.05 |

6.65 |

1.20 |

2.20 |

25.4 |

1.0 ~ 3.0 |

1600 |

360 |

1280 |

288 |

Min. |

1600 |

360 |

|

3.2 |

11.7 |

3.2 |

9.3 |

4-3 |

3.3 ~ 3.4 |

6.05 |

6.65 |

1.20 |

2.20 |

25.4 |

3.0 ~ 5.0 |

1360 |

306 |

Max. |

3200 |

719 |

||

|

3.2 |

14.0 |

3.2 |

11.6 |

4-4 |

3.3 ~ 3.4 |

6.05 |

6.65 |

1.20 |

2.20 |

25.4 |

5.0 ~ 7.0 |

2560 |

575 |

|||||

|

4.0 |

10.4 |

4.0 |

7.3 |

5-1 |

4.1 ~ 4.3 |

7.52 |

8.33 |

1.50 |

2.70 |

26.9 |

1.0 ~ 3.0 |

3200 |

719 |

2240 |

503 |

Min. |

3200 |

719 |

|

4.0 |

12.9 |

4.0 |

9.9 |

5-3 |

4.1 ~ 4.3 |

7.52 |

8.33 |

1.50 |

2.70 |

26.9 |

3.0 ~ 5.0 |

4160 |

935 |

Max. |

4800 |

1079 |

||

|

4.0 |

15.7 |

4.0 |

12.6 |

5-4 |

4.1 ~ 4.3 |

7.52 |

8.33 |

1.50 |

2.70 |

26.9 |

5.0 ~ 7.0 |

|||||||

|

4.8 |

12.8 |

4.8 |

9.3 |

6-1 |

4.9 ~ 5.1 |

9.05 |

10.00 |

1.60 |

3.30 |

26.9 |

1.5 ~ 3.5 |

4000 |

899 |

4400 |

989 |

Min. |

5100 |

1147 |

| 4.8 |

15.4 |

4.8 |

11.9 |

6-3 |

4.9 ~ 5.1 |

9.05 |

10.00 |

1.60 |

3.30 |

26.9 |

3.5 ~ 6.0 |

Max. |

6900 |

1551 |

||||

|

4.8 |

18.4 |

4.8 |

14.9 |

6-4 |

4.9 ~ 5.1 |

9.05 |

10.00 |

1.60 |

3.30 |

26.9 |

6.0 ~ 8.5 |

|||||||

|

6.4 |

16.8 |

6.4 |

8-1 |

6.6 ~ 7.0 |

12.45 |

13.40 |

3.10 |

4.93 |

4.93 |

1.5 ~ 5.5 |

8000 |

1798 |

14300 |

3214 |

Min. |

|||

|

6.4 |

20.8 |

6.4 |

8-2 |

6.6 ~ 7.0 |

12.45 |

13.40 |

3.10 |

4.93 |

28.0 |

5.0 ~ 9.0 |

Max. |

|||||||